Special considerations for cable inspection and testing

Power cable outage work should use the first type of work permit, work that does not require a power outage should use the second type of work permit. Before starting work, carefully review the relevant route maps, arrangement diagrams, and drawings of concealed engineering, and carefully verify whether the cable name and sign are consistent with the work permit before starting work after confirming that the safety measures are correct and reliable.

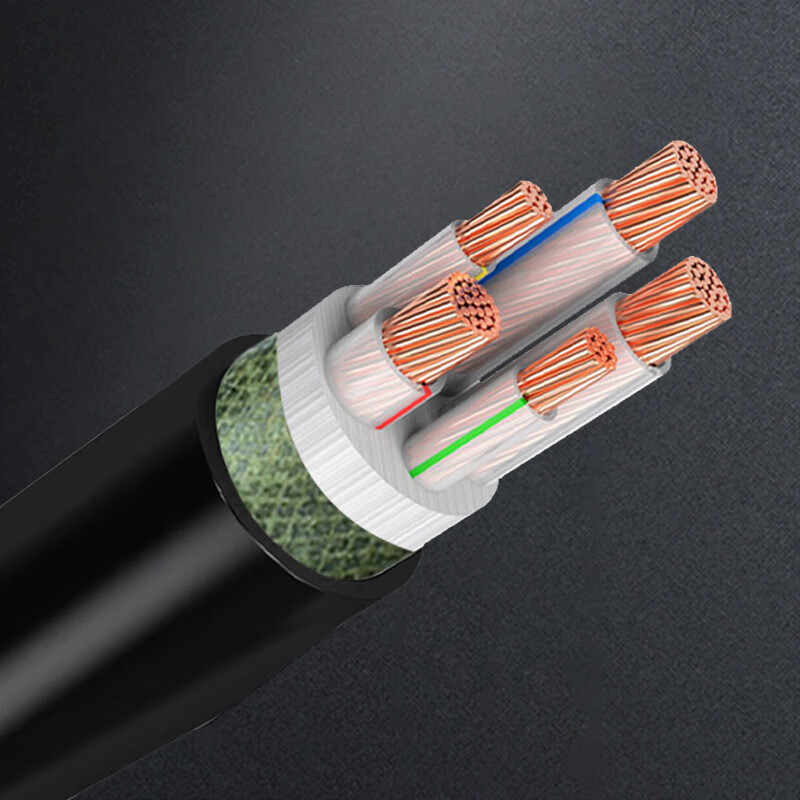

Power cables, as part of power lines, are widely used due to their low failure rate, safety, reliability, and flexible wiring. However, once a fault occurs, repair is difficult and dangerous, so special attention should be paid during repair and testing.

1. Pre-work Preparations

Power cable outage work should use a work permit, and work that does not require power outage should use a second type of work permit. Before starting work, carefully check the relevant route maps, arrangement diagrams, and drawings of concealed engineering. It is necessary to carefully check the cable name and whether the signboard matches the work permit before starting work after ensuring the safety measures are correct and reliable.

2. Precautions During Work

Confirm the cable that needs to be repaired during work.

The cables that need to be repaired can be divided into two types:

(1) Cables with terminal head failures or obvious fault points on the cable surface. These faulty cables have obvious fault signs and are easy to identify.

(2) Cables without exposed fault points on the surface. For these faulty cables, in addition to checking the data and verifying the cable name, a cable identifier must be used for identification to distinguish them from other energized cables in operation, especially in sections with many cables. It is particularly important to strictly distinguish between the cable to be repaired and other energized cables. This can also effectively prevent accidents caused by misidentification of cables due to incorrect cable signs, leading to the erroneous disconnection of energized cables. Cutting cables must have reliable safety protection measures. Before cutting the cable, it must be confirmed that it is the cable that needs to be cut and that the cable is de-energized. Then, after driving a grounded iron rod with a wooden handle (epoxy resin handle) into the cable core, the work can begin. The person holding the wooden handle should wear insulated gloves and stand on an insulated pad, paying special attention to ensuring good grounding of the iron rod. If the cable needs to be moved during work, it should be done carefully; avoid brute force to prevent damage to other cables in operation. Cable terminals must be installed according to process requirements to ensure quality and prevent accidents. After cable repair, carefully check the phases at both ends of the cable, remove the original phase color markers, and then install the correct phase color markers to prevent confusion between old and new phase colors.

3. Precautions During High-Voltage Testing

High-voltage testing of cables must strictly comply with the "Electrical Safety Work Regulations." Even under poor on-site working conditions, safety requirements cannot be compromised. The division of labor must be clear, and safety precautions should be detailed. The test site should be equipped with closed barriers or fences, and a "Stop, High Voltage Danger!" sign should be hung outside, with personnel on guard. In particular, personnel must also be stationed at the other end of the cable, and communication must be maintained to prevent emergencies. Testing equipment and wiring should meet safety requirements, and operation must be standardized. Attention should be concentrated during testing, and operators should stand on insulated mats. When changing wiring or at the end of the test, the test power should be disconnected first, discharged, and the high-voltage part of the high-voltage equipment should be short-circuited and grounded. During high-voltage DC testing, the cable should be discharged to ground several times and short-circuited to ground at each interval or at the end of the test before touching the cable.

4. Other Precautions

When opening manhole covers or cable trench covers, measures should be taken to prevent traffic accidents. Barriers should be set up around the manhole, clear warning signs should be posted, and obstacles should be set up to prevent vehicles from entering. At night, the cable manhole should be illuminated to prevent pedestrians or vehicles from falling into the manhole. Before entering the cable manhole, the foul gas in the manhole should be removed. Personnel in the manhole should wear safety helmets and take fire prevention, waterproofing, and anti-falling measures. Someone should be stationed at the manhole.

Tag:

Related Posts