How to improve the pass rate of fire-resistant cable fire resistance test

In recent years, the use of fire-resistant cables has been increasing.

In recent years, the use of fire-resistant cables has been increasing, mainly because users have recognized the performance of these cables, and the number of manufacturers producing these cables has also increased. Whether the quality of fire-resistant cables is guaranteed and remains stable in the long term is of vital importance. Generally, some companies, when developing fire-resistant cable products, first produce a sample product, send it to relevant national testing agencies for testing, obtain the test report, and then proceed with mass production. A few cable manufacturers have established their own fire-resistance testing laboratories. Fire-resistance testing is a test of the process results of the cables produced. The same process plan, but the cable performance produced at different times has certain differences. For enterprises producing fire-resistant cables, if the fire-resistance test pass rate of fire-resistant cables is 99%, then there is a 1% safety risk for fire-resistant cables, which is a 100% risk for users. In view of the above problems, the following describes how to improve the pass rate of fire-resistance tests for fire-resistant cables, from aspects such as raw materials, conductor selection, and process control:

1. Use copper conductors

Some Manufacturers use copper-clad aluminum conductors as cable conductor cores, but copper-clad aluminum conductors should not be selected for the conductors of fire-resistant cables; copper conductors should be used instead.

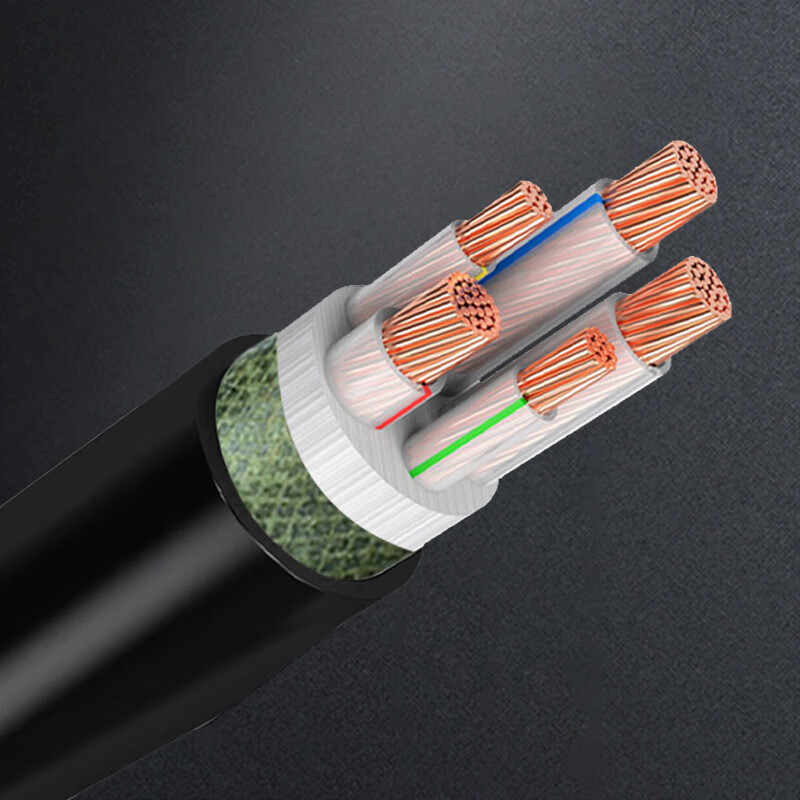

2. It is advisable to use circular compacted conductors

For circular cores with axial symmetry, the mica tape is tightly wrapped in all directions after wrapping. Therefore, the conductor structure of fire-resistant cables should preferably use circular compacted conductors.

The reason is: Some users propose that the conductor is a stranded soft structure conductor, which requires the enterprise to communicate with the user from the perspective of cable reliability and change to a circular compacted conductor. Soft stranded wires are easily damaged by the mica tape and are not suitable for fire-resistant cable conductors. However, some Manufacturers believe that whatever type of fire-resistant cable the user needs, the manufacturer should meet the user's needs. After all, users are not very clear about the details of the cable. Cables are closely related to human life, so cable Manufacturers must explain the relevant technical issues to users clearly. Fan-shaped conductors are also not advisable, as the wrapping pressure of the mica tape on fan-shaped conductors is unevenly distributed, easily scratching and damaging, thus leading to a decrease in electrical performance. In addition, from a cost perspective, the perimeter of the cross-section of a fan-shaped conductor is greater than that of a circular conductor, thus increasing the amount of the expensive material mica tape, although the outer diameter of the circular structure cable is slightly increased, and the amount of polyvinyl chloride sheath material used is increased. However, compared with the total cost of product materials, the overall cost is still lower for circular structure cables. Based on the above description, from the technical and economic analysis, the use of a circular structure for the conductors of fire-resistant power cables is optimal.

Tag:

Related Posts